hardness test of polymers and composites|how hardness testing works : mail order Hardness is the mechanical resistance of a material (specimen) to mechanical indentation by another harder body (indenter). The hardest natural material is the diamond, which is used for the indenter (industrial diamond). WEBGama começou sua trajetória no jornal Zero Hora, em 1964. Trabalhou ainda na Revista Veja por sete anos, além de dirigir a Gazeta Mercantil Regional Sul e o Jornal do Comércio. Há 11 horas .

{plog:ftitle_list}

WEBهاي كورة – كشفت تقارير صحفية إنجليزية عن خطة نادي ليفربول في إلغاء منصب المدير الرياضي بالنادي، وذلك مع شهر مارس المقبل.وأكدت صحيفة ذا أثلتيك أن ليفربول يدرس إلغاء منصب المدير الرياضي .

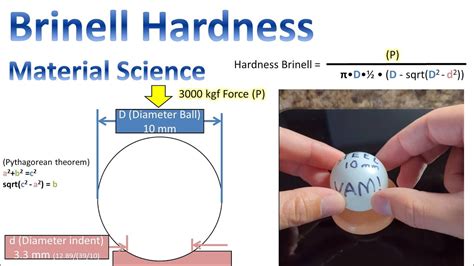

Tensile (tension), flexural, impact, shear, and compression with open and closed holes are the most typical standardized mechanical tests for polymer composites, and physical testing includes water absorption, density, void content, hardness, and scratch resistance. The most common standardized mechanical testing of polymer composites includes tensile (tension), flexural, impact [5], shear, and compression with open and closed .Hardness is the mechanical resistance of a material (specimen) to mechanical indentation by another harder body (indenter). The hardest natural material is the diamond, which is used for the indenter (industrial diamond). Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as well as quality .

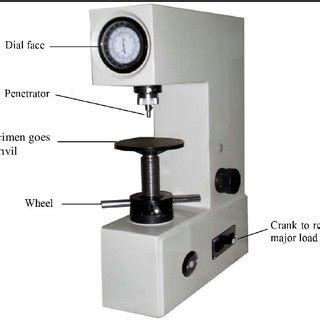

The Rockwell Hardness test is a hardness measurement based on the net increase in depth of impression as a load is applied. Hardness numbers have no units and are commonly given in . An experimental study has been conducted to determine the hardness properties and to analyse the thermal behaviour of green polymer composites with a particulate .

This test provided valuable insight into the exothermic reaction and how that correlated to the hardness and progression of cure. The test also showed that there is still a considerable spread in the hardness readings in the initial .

3.3 Hardness test. Brinell hardness test values for the epoxy-based hybrid composites are tabulated in Table 2. Here, it was seen that the samples with alternating layers of glass and coir fibers and additional 1 wt% .This compilation highlights the outstanding outline associated with the principles and experiments of mechanical and physical testing for both research and advanced technical applications of .A rough surface can cause the indenter to dig in more deeply, giving a falsely high hardness reading. What are the advantages of Rockwell M hardness? The Rockwell M hardness test is used to measure the hardness of a wide range of materials. For example, metals, plastics, ceramics, and composite materials (such as fiberglass and carbon fiber). This article presents a short overview of the most common techniques in non-destructive testing (NDT) of ceramic matrix composites (CMCs), including measurement of hardness.

The angle of the indenter used in the Vickers hardness test is 136 degrees . Therefore, the stress concentration factor because of the plastic restraint caused by the Vickers hardness test is calculated as 1.384. . The study also analyzed the ultimate tensile strength and modulus, flexural strength and modulus, elongation, impact and hardness test on the polymer and their composites as well as the morphology . In search of lightweight materials, polymer (biodegradable) composites are considered across the globe in engineering applications that suit their requirements towards environmental sustainability. In this study, the biodegradable polylactic acid (PLA) based polymer composite is fabricated by reinforcing chopped vetiver fibers (VFs) of varying proportions of .Rockwell hardness testing of plastics is described, and conversion charts correlating various scales are presented. . The Rockwell E, M, and R scales of hardness are commonly used for 'hard' polymers such as nylon, polystyrene, acetal, and polycarbonate. . Data sheets for over 180,000 metals, plastics, ceramics, and composites.

Review 5 on Metals, Ceramics, Polymers, and Composites A three-point bending test is performed on a glass specimen having a rectangular cross section of height d = 5 mm (0.2 in.) and width b = 10 mm (0.4 in.); the distance between support points is 45 mm (1.75 in.). = = ( ) ( )

Polymer Properties Hardness - Introduction Share. Hardness - Introduction What is the hardness of plastics? What materials show good hardness? What are the advantages of hardness? . What standard test methods measure hardness of plastics? ISO 2039-1:2001 — It determines the hardness of plastics. It uses the ball indentation method.OF POLYMER COMPOSITES Dr. S. Satheeskumar Professor, Department of Mechanical Engineering, CMR Institute of Technology, . The hardness test was conducted on a Shore D hardness test machine. 5 .Learn how Shore D Hardness test work, its significance to determine hardness of the material as well as what are common polymers this test is used for. . Polymer Name: Min Value Max Value ABS - Acrylonitrile Butadiene Styrene: 100.000 100.000 ABS Flame Retardant: 80.000 90.000 Acrylonitrile-Butadiene Styrene High Heat 80.000 85.000 .The plastics industry applies a variety of hardness testing methods, and each method addresses a different measurement objective. They can be in the nano, micro, or macro range. Plastics brochure Test methods Shore ISO 48-4, ISO 868, ASTM D2240 Ball indentation ISO 2039-1 Rockwell ISO 2039-2/ASTM D785 Instrumented hardness testing ISO 19278 Videos Testing .

To investigate the impact of used fibers as a reinforcement in the composite tubes, hardness and wear tests were done on them as follows. The Vickers microhardness test was performed on the samples with 5 repetitions according to ASTM-D4762 standard, and 15N force by a 1/16 in diameter penetrant tool [19].The pin on disk wear test was also performed on the . A common technique for determining the hardness of metals is the Rockwell hardness test, which can also be used to determine the hardness of composite materials and polymers. It is based on measuring the amount of material a diamond or tungsten carbide ball can penetrate beneath a specific amount of stress. 3.3 Hardness test. Brinell hardness test values for the epoxy-based hybrid composites are tabulated in Table 2. Here, it was seen that the samples with alternating layers of glass and coir fibers and additional 1 wt% charcoal (i.e. samples 2 and 3) have the highest Brinell hardness numbers of 46.27 and 49.21, respectively. The Vickers hardness test results of the composites exhibit pronounced variations contingent on their treatment and composition. The untreated short banana composite demonstrated a lower hardness value of .

Hardness testing measures the depth of indentation of a ball into a sample. Hardness property values are then calculated using tables derived from the empirical relationship between indentation depth and hardness levels. Our rubber and plastic testing labs can offer a comprehensive range of hardness measurements, including: The mechanical properties of PA6, aluminum reinforced PA6 polymer composites were studied in terms of tensile, flexural, impact and hardness tests. The PA6 composite containing 10 wt.% aluminum .

Mechanical properties of metal-polymer matrix composites were investigated experimentally. High density polyethylene (HDPE), polypropylene (PP), and polystyrene (PS) were used as the polymer .

Hardness and Surface Scratch Resistance of Basalt/Bagasse fibre Reinforced Poly Lactic Acid Polymer Composites July 2020 International Journal of Engineering Trends and Technology 68(6):13-21

Charisma Diamond One/DO, Admira Fusion x-tra/AFX, Omnichroma/OC, OptiShade/OS, Essentia Universal/EU, Zenchroma/ZC, Vittra APS Unique/VU were used in a three-point bending test to determine flexural strength (FS) and elastic modulus (EM); Vickers micro-hardness (VHN) and hardness-ratio (HR) were performed with a micro-hardness .

Friction and Wear of Polymer and Polymer Composites Ahmed Abdelbary . Deformation of the polymer surfaces can be introduced by the hardness, H. (2) Material disruption of at the asperity’s interaction. (3) Motion countered by the friction force (f), f = μL. where L normal load, The hardness (Shore D) test result for the hybrid polymer composites was shown in Fig. 5. The highest hardness value was obtained for sample-C as 93 SD. Sample-A with hardness 86 Sd (for 0.5 % wt. of sisal & polypropylene fibers) and Sample-D with hardness 90 SD (for 5 % wt. of sisal & polypropylene fibers) have been recorded.

of Plastics.4 The Shore Durometer hardness test was conducted, as it does not limit the sample thickness to 6 mm minimum, a requirement of the often-used Rockwell Hardness test. The Shore Durometer hardness test requires the testing location to be 12.0 mm from each edge. For this

9 flue pipe

Hardness evaluation is a widely used test to examine composite curing and, as a consequence, the efficiency of the light source. 37 It is applied especially to restorative materials that are used where high bite forces and stresses can exacerbate inherent material defects, resulting in inadequate fracture resistance of the materials. 38, 39 This chapter means to explain the tribological behavior of polymer-based materials, to support a beneficial introducing of those materials in actual applications based on test campaigns and their results. Generally, the designers have to take into consideration a set of tribological parameters, not only one, including friction coefficient, wear, temperature in . FDM-based 3D printers are presently the most popular consumer-level 3D printers for printing polymer composites that is based on extrusion additive manufacturing (AM) systems. . ASTM D2240, for the Shore Durometer Hardness test standard, covers the relative hardness of soft materials, usually elastomers. .The Rockwell Hardness test is a hardness measurement based on the net increase in depth of impression as a load is applied. Hardness numbers have no units and are commonly given in the R, L, M, E and K scales. Higher numbers indicate harder materials. Test Procedure: A standard specimen is placed on the surface of the Rockwell Hardness tester.

how hardness testing works

hardness testing standards explained

11 de out. de 2023 · masteruwuoficial. Soy un creador de contenido al quien le gusta el H y las monas shinas, e creado este grupo con el fin de compartir gustos. Esto va tanto para .

hardness test of polymers and composites|how hardness testing works